ANTICORROSION PROTECTION FOR OIL&GAS PIPELINES

- All

Global Transmission Sleeve

The GTS-65 system provides superior corrosion protection and excellent bonding on pipelines operating up to 65°C. GTS-65-EN has been designed with a unique adhesive technology that remains “open” longer than traditional adhesives

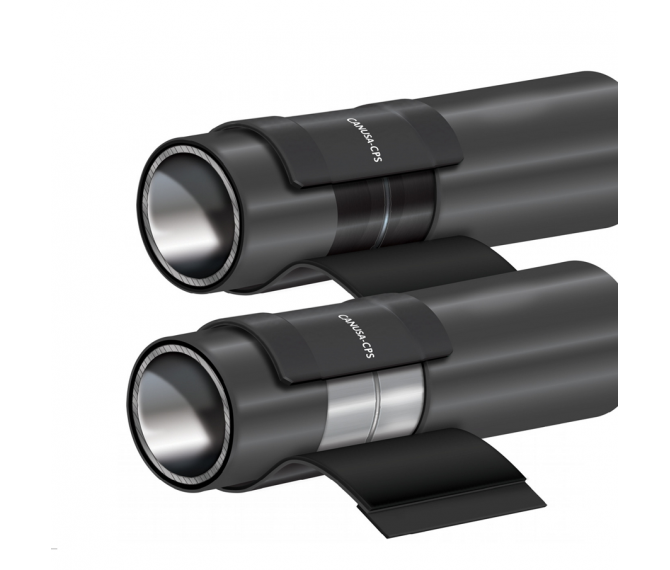

Casing Snap-Fit Sleeves

Heat-shrinkable wrap-around sleeves specifically designed to provide a waterproof seal on pipeline casings operating at constant temperatures of up to 60°C

Advanced girth-weld protection for pipes

The TBK Directional Drilling system is specifically designed to protect welded joints on PE, FBE and HPCC coated pipelines in directional drilling applications.

Outer Pipeline Mechanical Protection

AroEagle is composite abrasion resistant overcoat comprised of fiberglass cloth and pre-impregnated flexible resin that is activated by water and cured within minutes.

Force-cure epoxy for superior 3-layer corrosion protection

Canusa Liquid Epoxy Type E is a force cured, two-part epoxy used as the primary layer with Canusa 3-layer systems, such as GTS-PE and GTS-65

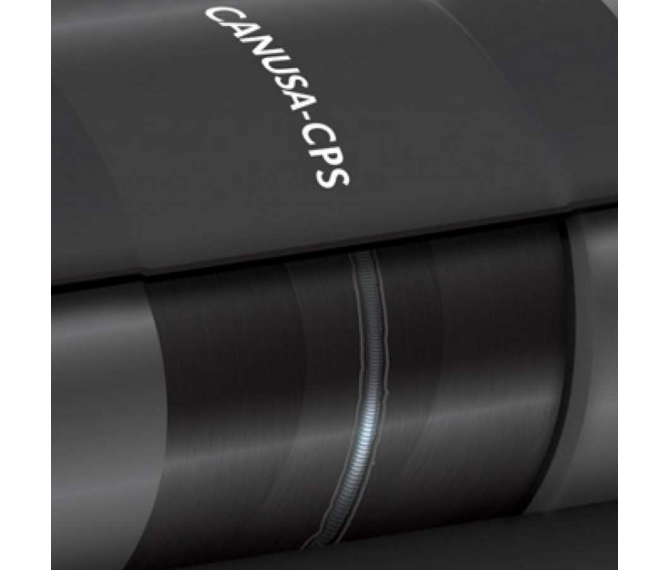

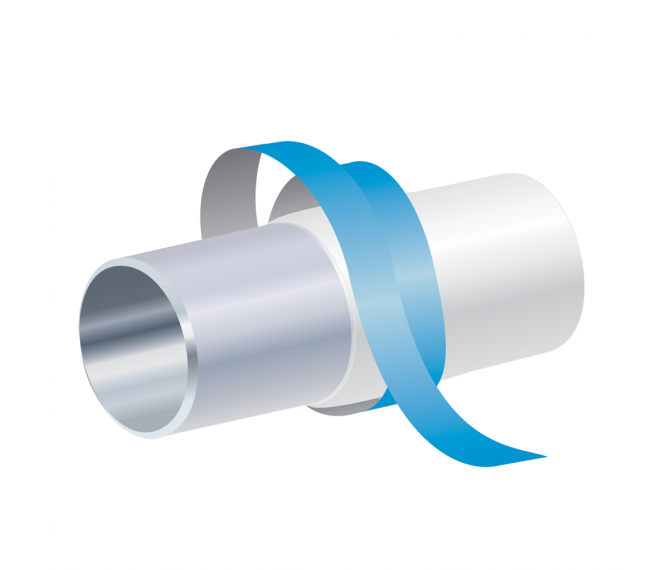

Primerless Crosslinked Protective Tape

It consists of a crosslinked polyolefin backing, coated with a protective, heat sensitive anti-corrosion adhesive which effectively bonds to steel substrates and common pipeline coatings.

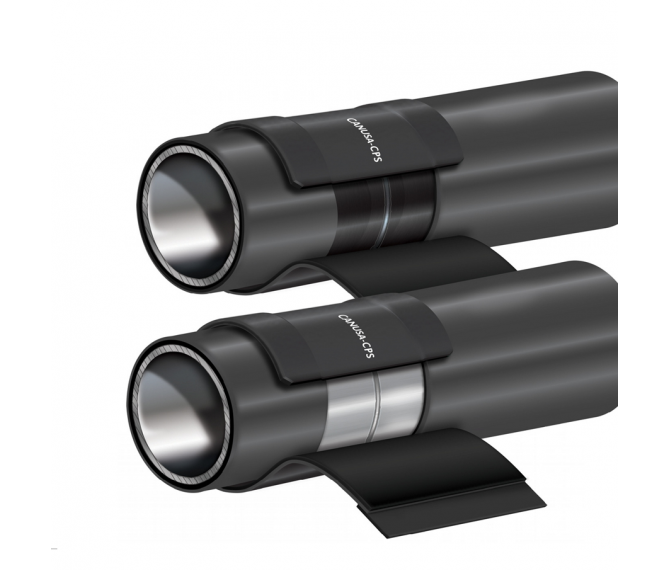

Wrapid Shield™ PE

Canusa-CPS’ Wrapid Shield™ PE is an advanced extruded and blown polyethylene Rock Shield system engineered to provide high impact resistance and compressive strength when usedas a protective layer over top of anti-corrosion coatings. The material resists impact damage.

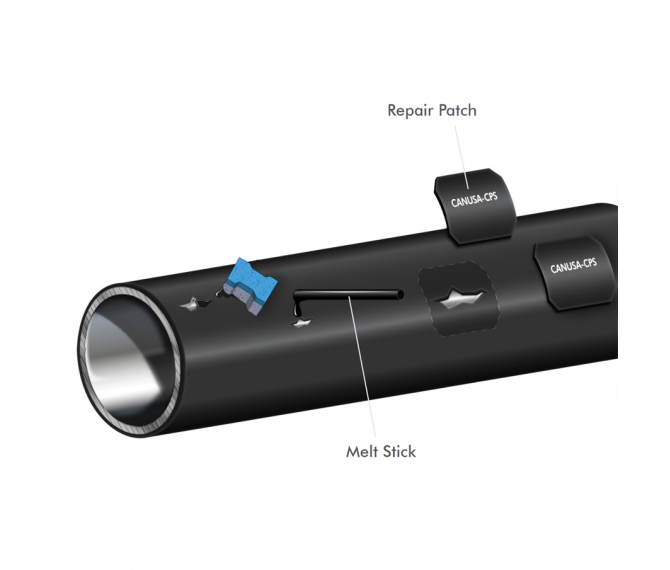

Coating repair products for corrosion protection

Canusa’s Repair Products are used to repair and/or fill voids in damaged coatings.

Durable PVC tape

End Seal Tape is a durable PVC tape, featuring a modified pressure-activated adhesive, with outstanding water resistance.

The GTS-50 system provides superior corrosion protection and excellent bonding on pipelines operating up to 55°C. GTS-50 has been designed with a unique adhesive technology that remains open longer than traditional adhesives. GTS-50 is a cost effective al